end mill cutter geometry

Side milling curved surface milling and drilling are possible only by one tool. Their specialized end geometry reduces the circular end marks that are left behind from traditional metal cutting end mills leaving a cleaner finish with minimal.

Sem Image Of The Micro End Mill Clearly Indicating The Tool Geometry Download Scientific Diagram

End mill A multi-functional tool which has cutting edges on the periphery and an end face.

. Endmill Design Basics Angular Edge The cutting edge that is a straight line and forms an angle with the cutter axis. With our skill and expertise and the best equipment available we are able to recondition your cutting tools. The coordinate values of any point P i on the cutting edge can be determined from the NURBS curve representation if given the corresponding parameter u i.

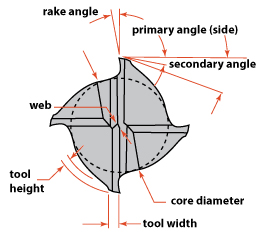

It is measured from the start of the necked portion to the bottom of the cutting end of the tool. The axial Rake angle of the cutter is equal to the Back Rack of the single point tool. The cut that an Angular edge tool produces will not be as flat as a helical cutting edge.

These have one cutting edge ground right to the centre and thus can be used to drill directly into the workpiece when creating a recess. While a drill bit can only cut in the axial direction most milling bits can cut in the radial direction. The final link to making good.

The cutting edge geometry for a ball end mill is shown in figure 2. It comes with a trade-off unfortunately. The body portion of the end-mill tool is located between the shank and the point.

Both types provide longer tool life than square end mills. An end mill is a type of milling cutter a cutting tool used in industrial milling applications. The unified models of end mills with different end geometries.

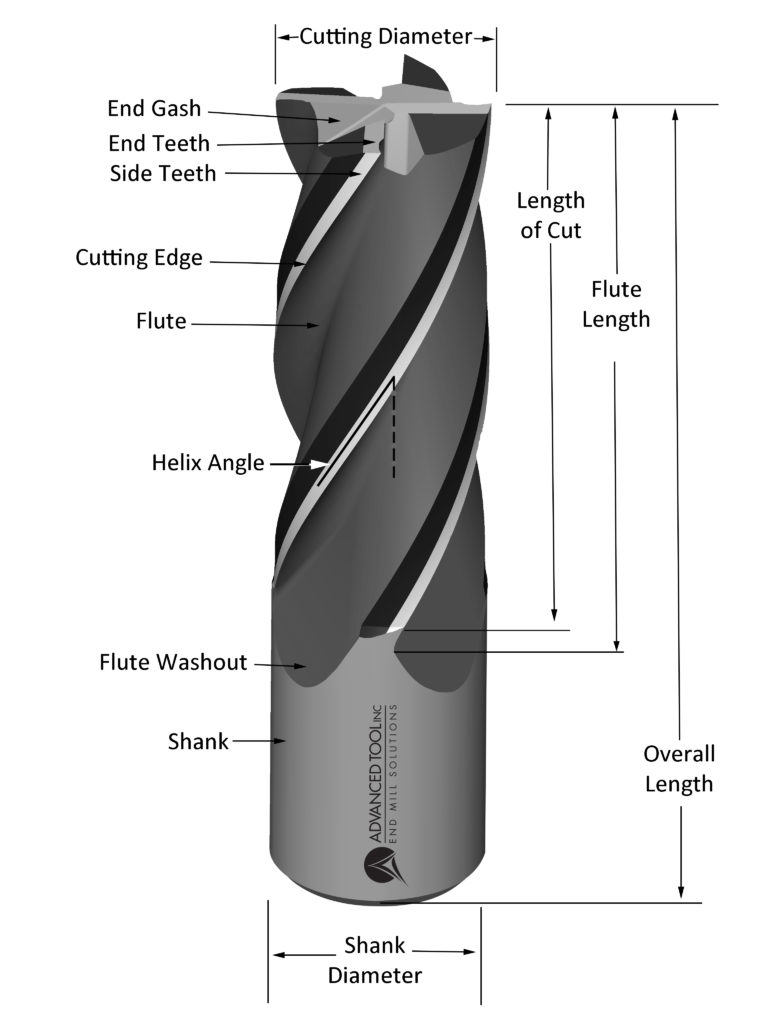

The overall reach of an end mill or length below shank LBS is a dimension that describes the necked length of reached tools. Corner chamfer end mills have an angled cutting edge and are used where a specific radius size is not required. While end mills have traditionally had four cutting flutes recently cutters with three flutes and higher helix angles have been introduced.

The latest addition to our popular SSI series is the SSI-7. The five important angles involved in the making of the millcutter are. Geometry Geometry is a huge determinant of end mill performance and there is a lot to cover.

Free easy returns on millions of items. Lets start with the basic helix itself. End Mill End Clearance Dish Angle Angle Between End of Cutting Edge and Perpendicular to the Cutter Axis Dish Ensures a flat Surface is Produced Gash Notch Secondary Cuts to Provide Chip Space at Corners and Ends Forming the End Cutting Edge when Feeding Axially Gash Angle Relief Angle of the Gash Feature End Mill Flutes.

This is a seven flute variably-indexed tool designed specifically for high efficiency machining in ferrous alloys. A cutting tool for making inside wall of a drilled hole smooth and accurate. We guarantee that you will be pleased with the tremendous productivity.

Up to 1 1195. Hence end mills with a higher helix angle tend to produce a better surface finish on the workpiece. This shop boosted cutting speed and tool life on a troublesome tool steel application by switching to SGS Tool Companys Z-Carb AP end mill which features a custom geometry designed to reduce chatter.

Contour machining is when an end mill machines around the workpiece at the same depth then sinks deeper repeats the operation shown in the image. We are a high end CNC Tool Cutter Grinding shop providing quality that is normally not found in the tool sharpening industry. These tools employ an improved cutting action and rigidity due to the higher flute count.

The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep- pocket milling applications. End Mills where the metal hits the work piece. Contour machining is advantageous over copy machining because machining on level surfaces means that any.

Up to 12 595. They make the chips actually fly. End mill cutter geometry.

Variably spaced flutes variable helix angles and variable rake angles. Up to 38 495. The radial Rake angle of the milling cutter is equal to the side rake of the single point tool.

Each of the 18 end mill cutters cuts a pocket of 100 3 64 mm and 15 mm in depth on the two faces of an aluminium 5083 plate of 500 3 280 mm and 60 mm in depth. Read customer reviews find best sellers. Increasing the helix angle will reduce the cutting forces and the amount of heat and vibration generated during the milling process.

Recommended Starting Feed per Tooth Fz in Relation to of Radial Engagement ae. To manufacture an end-mill tool a grinder is typically used to grind a flute face and a corresponding cutting edge on the body of the end. The two faces were finished with a.

The parameter u i normalizes points at equal spacing along the rotational axis z axis of the tool. Three Flute Plastic Cutting End Mills can reduce or eliminate the need to hand-deburr a part. Copy machining is where the end mill moves linearly following the workpiece cross-sectional geometry.

Up to 34 995. Axial Runout The difference between the highest and lowest indicator reading that is taken at the face of a cutter near the outer diameter. Ad Browse discover thousands of brands.

It is distinguished from the drill bit in its application geometry and manufacture. Mill 1-18 End Mills Cylindrical Shank Metric - 2613789. In addition to seven flutes we have also built this series on a new premium substrate.

The constructive elements and geometric parameters of single flute end mill cutters are defined on the most characteristic and often applied in practice tool universal normal with right hand spiral for right hand cutting and polyhedral profile-ground style manufactured form high- speed steel HSS Co8 fig. Th e surfaces meant for cutting operations known as flutes are modeled as helicoidal. Brief Geometry of the Milling Cutter.

Exotic geometries serve many functions and we cant possibly describe all the many variations out there in one article but lets go through a few of the more common examples. General-purpose end mills typically have helix angles around 30. SGS Z-Carb series end mills reduce chatter in three ways.

Free shipping on qualified orders. Cutting edges are only on a top. The point is formed at an opposite end of the tool from the shank portion and typically includes one or more cutting edges.

Hello everyone welcome to At-Man Unlimited. Corner radius end mills have a rounded cutting edge and are used where a specific radius size is required.

End Mill Terminology Mitsubishi Materials Corporation

Two Flute End Mill Cutter Geometry Centre Cutting Type Download Scientific Diagram

Geometry Of A Standard End Mill Download Scientific Diagram

Hss Endmill Pt Metro Rekayasa Indonesia

Endmill Design Basics Mastercut Tool Corp

Ball End Milling Cutter Geometry 16 Download Scientific Diagram

End Mill An Overview Sciencedirect Topics

Walter Advance Line Of Milling Cutters Walter Prototyp Youtube

End Mills Cad Cam Engineering Worldwide

Endmill Selection Guide Redline Tools Redline Tools

Hss Endmill Pt Metro Rekayasa Indonesia

End Mill An Overview Sciencedirect Topics

End Mill Terminology Mitsubishi Materials Corporation

Two Flute End Mill Cutter Geometry Front View Download Scientific Diagram

End Mill Nomenclature Download Scientific Diagram

Technical Information Destiny Tool

Illustration Of Ball End Milling Cutter Geometry A C And The Cutter Download Scientific Diagram